The Anatomy of Great Plastic Wide Mouth Bottles

The Anatomy of Great Plastic Wide Mouth Bottles:

10 Parts to Know

Bottles come in all forms and sizes. That is why it’s vital to understand their anatomy to enable you to choose the most suitable one for your packaging needs. The mouth of a bottle can be sealed using an exterior bottle cap, an inner seal, internal stopper or closure. The type of product you deal with determines the kind of bottle you should use. Plastic bottles are best suited for keeping liquids like medicine, vitamins, oils, soft drinks, and water. They are popular because they are great moisture barriers and highly resistant to breakage from impact, whether during production or transportation. Also, they are affordable. Best of all, plastic wide mouth bottles are available in various types and sizes.

Amber Polyethylene Terephthalate (PET) plastic wide mouth bottles are best suited for storing pills, veterinary, and pharmaceutical products. These wide mouth bottles allow you to see the contents inside and can be used with a variety of closures. Their sizes range from 75cc to 750cc.

Clear PET plastic wide mouth round bottles are available in a variety of sizes from 75cc to 960 ml. They are lightweight, resistant to impact, and offer easy access to the contents inside. These bottles are often used in the laboratories and for storing items such as nutritional supplements..

White HDPE plastic wide mouth bottles are opaque white in color, recyclable and perfect for bulk packaging. Their size ranges from 75cc to 750cc. These wide mouth bottles are normally used for label application and silkscreen decoration.

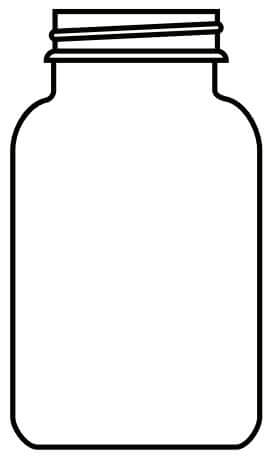

Plastic Wide Mouth Bottles – 10 Parts to Know

Let’s take a detailed look at the architecture of plastic wide mouth bottles.

#1 FINISH – This is the part of wide mouth bottles above the neck, reaching up to the opening of a bottle. The finish is usually shaped in line with the type of closure used on the bottle. According to history, creating this part was the last step that craftsmen took when making containers, and hence the name.

#2 SEALING SURFACE OR LAND -The sealing surface or land is the flat circular part of the finish that comes in direct contact with any closure used to seal wide mouth bottles. The land is usually flat to prevent contents from leaking from the container.

#3 THREAD -This is the section of the finish that has a spiral shape. It is where the closure is twisted to seal the container. The size of the bottle neck determines the thread – standards range from between 5 threads per inch to 12 threads per inch. A well engineered thread will protect the bottle contents by keeping them fresh and free from being tampered with which can lead to product damage.

#3 THREAD -This is the section of the finish that has a spiral shape. It is where the closure is twisted to seal the container. The size of the bottle neck determines the thread – standards range from between 5 threads per inch to 12 threads per inch. A well engineered thread will protect the bottle contents by keeping them fresh and free from being tampered with which can lead to product damage.

#4 TRANSFER BEAD – Also known as the neck ring, this is the horizontal ridge found at the bottom of the finish section. This collar of plastic is used during the molding process and can be used to provide tamper evidence for your packaging.

#5 NECK – The neck area is found below the finish. This is the section where the narrow part of wide mouth bottles gets smaller and joins the finish.

#6 SHOULDER – This section is where the base of the neck joins with the body. It is the widest part of the container. The shoulder’s slope can tell you how fast a product can spill out when you turn the container upside down.

#7 LABEL PANEL -The label panel is the flat area below the shoulder and just before the bottom of wide mouth bottles. This is the section where labels or print decorations are placed.

#8 BODY – The body, also known as the sidewall, refers to the central part of the container. The body of most vessels usually is vertical. However, there can be exceptions.

#9 BOTTOM – This is the foundation of wide mouth bottles. As the name suggests, it is found on the lower section of the bottle and falls right under the body. The bottom is divided into sections like the base, push-up, and heel. The heel refers to the section where the sidewall starts curving to form the base, which is the bottom part of the container. The push-up is part of the base and is the section that provides a plastic wide-mouth bottle with stability, and includes room for marking the base with details like registration numbers, and any labeling.

#10 PARTING LINE – This is a vertical line from the base to the finish. It’s where the two halves of the container meet during molding to form a full bottle.

Silver Spur Corporation can provide you with a variety of different types and sizes of plastic wide mouth bottles in line with the product you want to package. Get in touch with us, and we’ll ensure you get the best plastic bottle for your packaging needs.